Total Water Treatment

|

An Overall View and

Summary of Some of the Advantages of Our Tecnology  Naval CDI Prototype Naval CDI Prototype

Our Total Water Treatment Process is a modified version of Capacitve Deionization (CDI). It does not depend upon high temperature or pressure nor does it require the use of membranes. Ions, microorganisms and microcontaminants are removed by applying a potential to porous conducting electrodes coated with nano-films, developed and perfected by the principals of Ur-Water. Essentially, a solution of ions flows through a highly porous conducting pair of electrodes. This process causes charged ions and organisms to be deposited on the electrode of opposite charge. In this process, energy is actually stored in a capacitive format at the interface between the electrode and the solution. This energy is recovered for use in the next regeneration cycle. Furthermore, our porous electrodes are kept clean by our unique technology. Waste water is minimized and controlled by the level of ion removal desired, by potential applied, and as well by the duration of the cycle for regeneration. Since the Ur-Water process uses no salt, the environmental issues currently confronting various governmental units are greatly diminished.

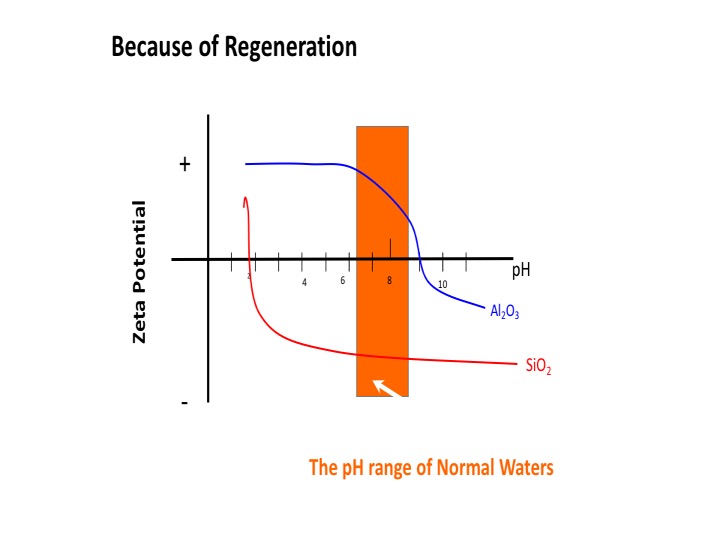

Our porous electrodes are unique in that we have a patented process whereby each of a set of two pairs of electrodes have a different surface charge at the natural pH of drinking waters. This feature was developed by two of the principals in our company and has been patented by the University of Wisconsin Alumni Research Foundation (WARF). Ur-Water holds a license to this technology. At present, we have built several prototype water treatment systems which are currently being tested in US Naval facilities as well as in private companies. Testing is being conducted not only for deionization but as well for the removal of heavy metals, trihalomethanes and for the treatment of mining waste waters. |

Importance of Nanoparticulate Oxide Coatings

We have a 40+ year history of producing nanoparticulate oxides whose primary particle size is between 2-8 nanometers.

These particles are employed in our composite electrodes to increase surface area, change surface chemistry and improve wettability. As can be seen, depending upon the nature of the oxide and the pH of the solution, these coatings can provide a natural surface potential that can be different or each in a pair of biased electrodes. This provides an opportunity to use a reverse bias upon regenerating our electrodes without the crossover of ions. This would be called now membrane capacitive deionization. However, we DO NOT USE MEMBRANES and therefore avoid membrane fouling and increase throughput.

As an electrochemical system, we have the capacity to change voltages and currents and this provides further flexibility to the system. Where reverse osmosis is being used quite successfully in many scenarios, the ability to control the quality and quantity of water produced is controlled only by the membranes employed. These membranes are subject to fouling and and produce a lower throughput of product waters. Here we have the ability to control the quality, and quantity of the water we produce regardless of source and can in addition reduce the amount of brines produced in the process. Furthermore, the ability to exactly control potentials applied, allows one to tailor or specifically remove metals depending upon the customer needs. There is also the capability in our system to perform a type of advanced oxidation which provides an additional benefit to those that which to treat pathogenic organisms. We believe that this total flexibility is unique in the water treatment arena and we are committed to optimizing these features of our device.

|

Operational Aspects of The Technology: Removal and Regeneration

In the above picture you will see an annimated schematic of the electrosorption process leading to the removal of ions and the delivery of potable water. This is the electrochemical part of the process. However, bear in mind that we are also removing organic contaminants as well as pathogens in this process. In addition, unlike a carbon adsorption system, our unique process allows the porous electrodes to be cleaned of contaminating organics and sterilized with respect to pathogens..

In the regeneration cycle, our process is designed to greatly reduce brine waste. In the above picture of, you will see that our process essentially removes electro-sorbed ions. However, due to our unique nanoparticulate oxide coated electrodes we can apply a reverse potential without ion-crossover. Also, energy stored in the removal process is utilized in this regeneration cycle.

|